A centrifugal pump moves fluid by transferring rotational energy from one or more impellers or driven rotors. In the impeller, water is drawn into the axis and thrown out through the blade tips by centrifugal force.

Fluid flows from the impeller to the pump output, increasing its velocity and pressure. Pump casings are designed to compress fluid entering the pump, guide it to the impeller, and then slow and regulate it before discharge.

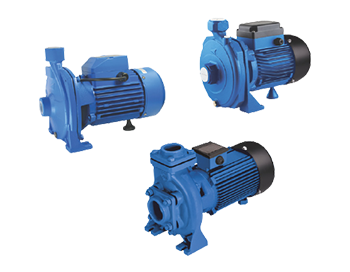

Features and Benefits

Centrifugal pumps have a simple construction with fewer parts. They have a small head but are appropriate for large discharges. It requires priming and provides continuous delivery. Major benefits of centrifugal pumps are:

Corrosion resistance

Centrifugal pumps can be extensively used in the process and manufacturing industries that transfer different types of fluids. The pumps are made to withstand corrosive materials. They have a long service life. There is no risk of a leak. Hazardous liquids can be pumped efficiently without any leakages.

Low Maintenance

Centrifugal pumps are reliable and can operate in extreme conditions. The robust construction of the pumps eliminates the need for frequent maintenance. They have a low routine maintenance requirement.

Versatile

Centrifugal pumps are available in a wide variety of sizes and they can be configured to provide solutions for multiple uses.

Energy Efficient

In terms of energy efficiency, centrifugal pumps rank high. The pumping technology reduces the cost of ownership.